PUMA AUTOMATIC CONTINUOUS SANDWICH PANEL

PUMA AUTOMATIC CONTINUOUS SANDWICH PANEL

or

Call (+34) 916 587 260

Description

AUTOMATIC & CONTINUOUS SANDWICH PANEL PRODUCTION LINE

Manufacturer: PUMA

This automatic continuous sandwich panel production line is designed for wall and roof panels. It is fully operational.

The line includes:

1. Top roll forming line

- Coil loading table & Single expandable mandrel Uncoiler

- Polyethilen film application unit

- 8-step roll forming line

- 12m strip support & guiding unit

- Steel structure frame for supporting all above equipment

2. Bottom roll forming line

- Coil car

- Single expandable mandrel uncoiler

- CORONA effect unit

- 24-step roll forming line

3. Pre-heating electric furnace

4. Foaming unit

- Foaming unit, manufacturer, type, PUR – PIR

5. 21m double belt conveyor

6. Automatic spacer feeding system

7. Flying saw

- Bandsawing unit with dust exhaust system

- Double disc cutting integrated in flyng saw

8. Cooling / Exit roll conveyor

9. Vertical Paternoster cooling system

10. Automatic panel stacking system

11. Orbital wrapping line with automatic insertion of lower spacers, manufactured by Robopac

12. Complete hydraulics, pneumatics & electric system

13. Existing tanks for chemical (excluding pentane)

14. Documentation

15. Existing tooling and spares

Specifications

| Manufacturer | PUMA |

| Model | AUTOMATIC CONTINUOUS SANDWICH PANEL |

| Year | 2007 |

| Condition | Used |

| Stock Number | 4006 |

| Line speed | Max. 10 m/min |

| Panel length | 2.000 mm – 15.300 mm |

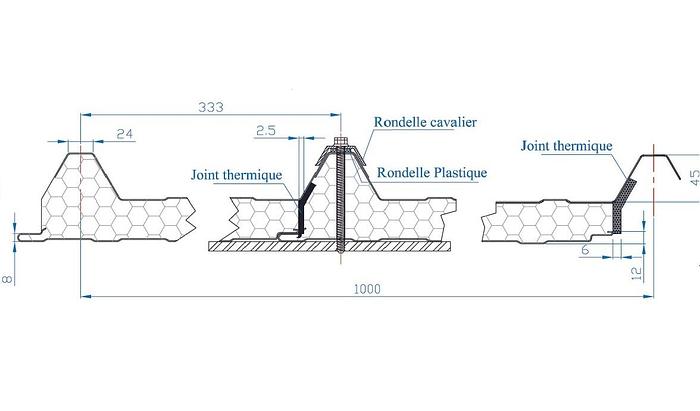

| Roof | Configuration G4 |

| Roof panel thickness | 30 - 40 - 50 - 60 - 80 mm |

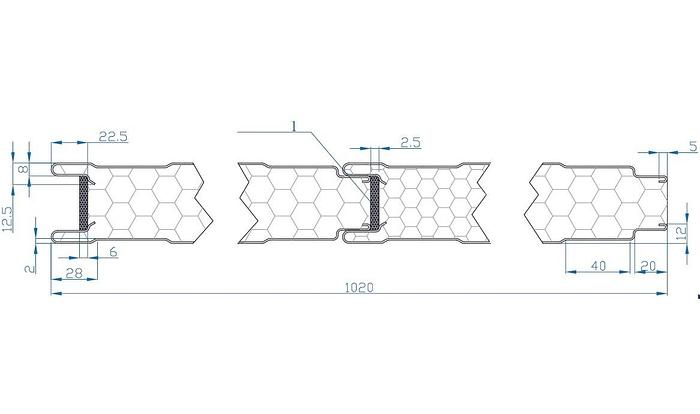

| Wall thickness | 30 - 40 - 50 - 60 - 80 - 100 - 120 - 140 - 160 mm |